Why choose Surgical Consumables?

2025-08-21

Surgical consumables are essential single-use or limited-use medical products required during surgeries, medical procedures, and patient care. They play a critical role in ensuring safety, efficiency, and hygiene across various healthcare settings, including hospitals, clinics, and ambulatory surgical centers. Unlike reusable surgical instruments, these items are typically disposed of after a single use to prevent contamination and maintain strict infection control.

Why They Matter

-

Infection Control: Disposable items reduce cross-contamination risks.

-

Operational Efficiency: Pre-packaged consumables save preparation time.

-

Patient Safety: Use of sterile materials ensures minimal exposure to pathogens.

-

Compliance with Standards: Proper consumables help healthcare facilities adhere to WHO and ISO guidelines.

With an ever-expanding range of products available, selecting the right surgical consumables involves evaluating material quality, sterility assurance, usability, and compatibility with various surgical procedures.

Types of Surgical Consumables and Product Parameters

Surgical consumables encompass a wide variety of products designed for different stages of medical procedures, from preparation and operation to postoperative care. Below is an overview of the primary categories and their professional specifications.

| Category | Description | Material | Sterility Level | Application |

|---|---|---|---|---|

| Surgical Gloves | Protect hands from contamination and infection | Latex, Nitrile, Vinyl | Sterile & Non-Sterile | All types of surgeries |

| Surgical Masks | Prevent droplet transmission | Non-woven fabric | Non-Sterile | General & high-risk care |

| Surgical Drapes | Maintain a sterile field around operation sites | SMS, PE-coated fabrics | Sterile | Major & minor surgeries |

| Gowns & Aprons | Protect surgical staff from fluids and debris | SMS, PP, PE-laminated | Sterile & Non-Sterile | Operation theaters |

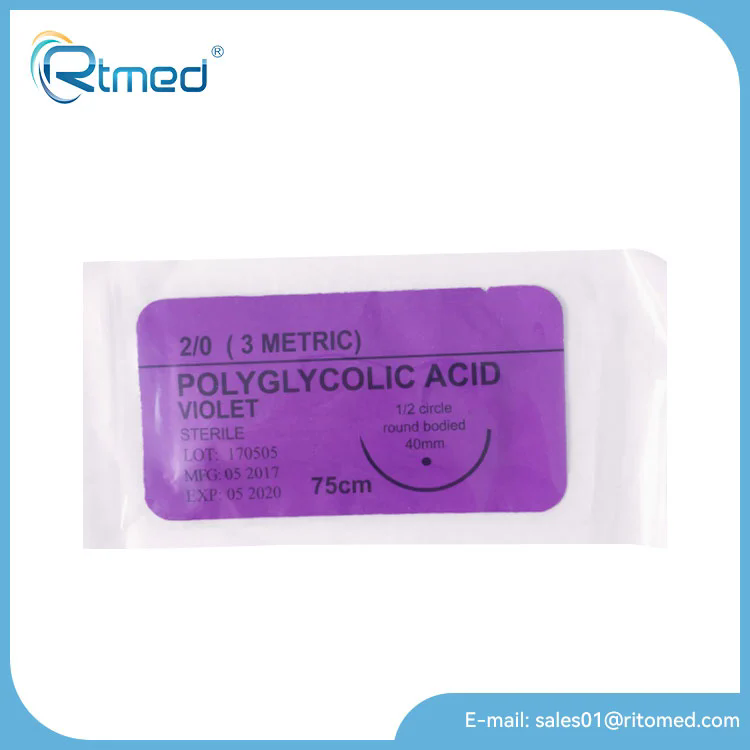

| Sutures & Staples | Close wounds and incisions | Nylon, Silk, PDS, etc. | Sterile | General and specialty use |

| Swabs & Sponges | Absorb blood and exudates | Cotton, Gauze | Sterile & Non-Sterile | Wound care & surgeries |

| Catheters & Tubes | Drain fluids or deliver medications | Silicone, PVC, Latex | Sterile | Postoperative care |

| Surgical Packs | Pre-assembled kits tailored for procedures | Mixed materials | Sterile | Streamlined surgeries |

Key Selection Factors

-

Material Quality – Choose biocompatible materials to avoid allergic reactions.

-

Sterilization Process – Ensure products comply with ISO 11135 (ethylene oxide) or ISO 17665 (steam sterilization).

-

Packaging Integrity – Check for tamper-evident seals and moisture barriers.

-

Procedure-Specific Design – Select consumables tailored to the surgical specialty.

-

Cost vs. Quality Balance – Optimize procurement without compromising patient safety.

By understanding these specifications, healthcare providers can make informed purchasing decisions that enhance patient care while reducing operational risks.

How to Select the Best Surgical Consumables for Your Facility

Choosing the right surgical consumables requires a comprehensive approach. A single misstep, such as using poorly sterilized gloves or inferior sutures, can compromise both patient safety and hospital reputation. Below are the best practices for procurement and selection.

Compliance with International Standards

Always ensure that surgical consumables comply with certifications such as:

-

ISO 13485 – Quality management systems for medical devices

-

CE Marking – European conformity for medical products

-

FDA Approval – Safety and efficacy for U.S. healthcare use

-

WHO Guidelines – Infection prevention and control protocols

Evaluate Supplier Reliability

Partner with reputable suppliers who provide:

-

Product traceability

-

Consistent quality control reports

-

Transparent sterilization validation

-

On-time delivery and supply chain stability

Focus on Sterility and Shelf Life

-

Check expiry dates to avoid using degraded products.

-

Ensure double-layer sterile packaging for critical items like drapes and sutures.

-

Store consumables in controlled environments to maintain sterility.

Consider Procedure-Specific Kits

Pre-assembled surgical packs are becoming increasingly popular because they:

-

Reduce preparation time.

-

Ensure all necessary items are available.

-

Lower the risk of missing components mid-procedure.

Sustainability in Consumables

With increasing environmental awareness, many facilities now adopt eco-friendly consumables:

-

Biodegradable materials for gowns and drapes.

-

Recyclable packaging to reduce medical waste.

-

Suppliers with ISO 14001 certification for environmental management.

FAQs, Brand Integration, and Contact Information

Surgical Consumables FAQs

Q1: What are the most critical factors when choosing surgical consumables?

A1: The top considerations are material quality, sterility assurance, regulatory compliance, and procedure compatibility. For example, gloves made from nitrile are preferable in sensitive surgeries due to their superior barrier properties and reduced allergen risks. Always ensure consumables meet international certifications like ISO, CE, or FDA standards to maintain patient safety.

Q2: How can hospitals control costs without compromising quality?

A2: Hospitals can adopt bulk purchasing strategies, partner with reliable suppliers, and consider pre-packed surgical kits to streamline operations. While price is important, compromising on quality can lead to infections, longer patient stays, and higher costs in the long run.

Rito: Your Trusted Partner in Surgical Consumables

When it comes to high-quality surgical consumables, Rito stands out as a trusted global supplier committed to safety, performance, and innovation. Our products are manufactured under strict quality control standards, ensuring compliance with ISO, CE, and FDA regulations. From gloves and masks to comprehensive surgical packs, we deliver solutions tailored to the unique needs of healthcare providers.

Choosing Rito means:

-

Access to premium-grade, fully sterilized consumables.

-

Reliable supply chain with fast and secure delivery.

-

Dedicated customer support and technical consultation.

If you’re looking to improve patient outcomes and streamline surgical operations, contact us to learn more about our full range of surgical consumables and customized solutions.